Introduction

In present day aggressive marketplace, product exceptional and shopper pride are paramount. Businesses try to convey https://service.opendi.us/verify?sid=721591&key=684ff5d633dd8 marvelous merchandise that not simplest meet yet exceed visitor expectations. One customarily disregarded facet that plays a principal function in attaining this purpose is calibration. Calibration refers to the strategy of configuring an software or system to furnish a outcome for a sample inside a suitable vary. This article dives into how calibration influences product high quality and customer satisfaction, exploring its significance throughout a range of industries, methodologies, and fabulous practices.

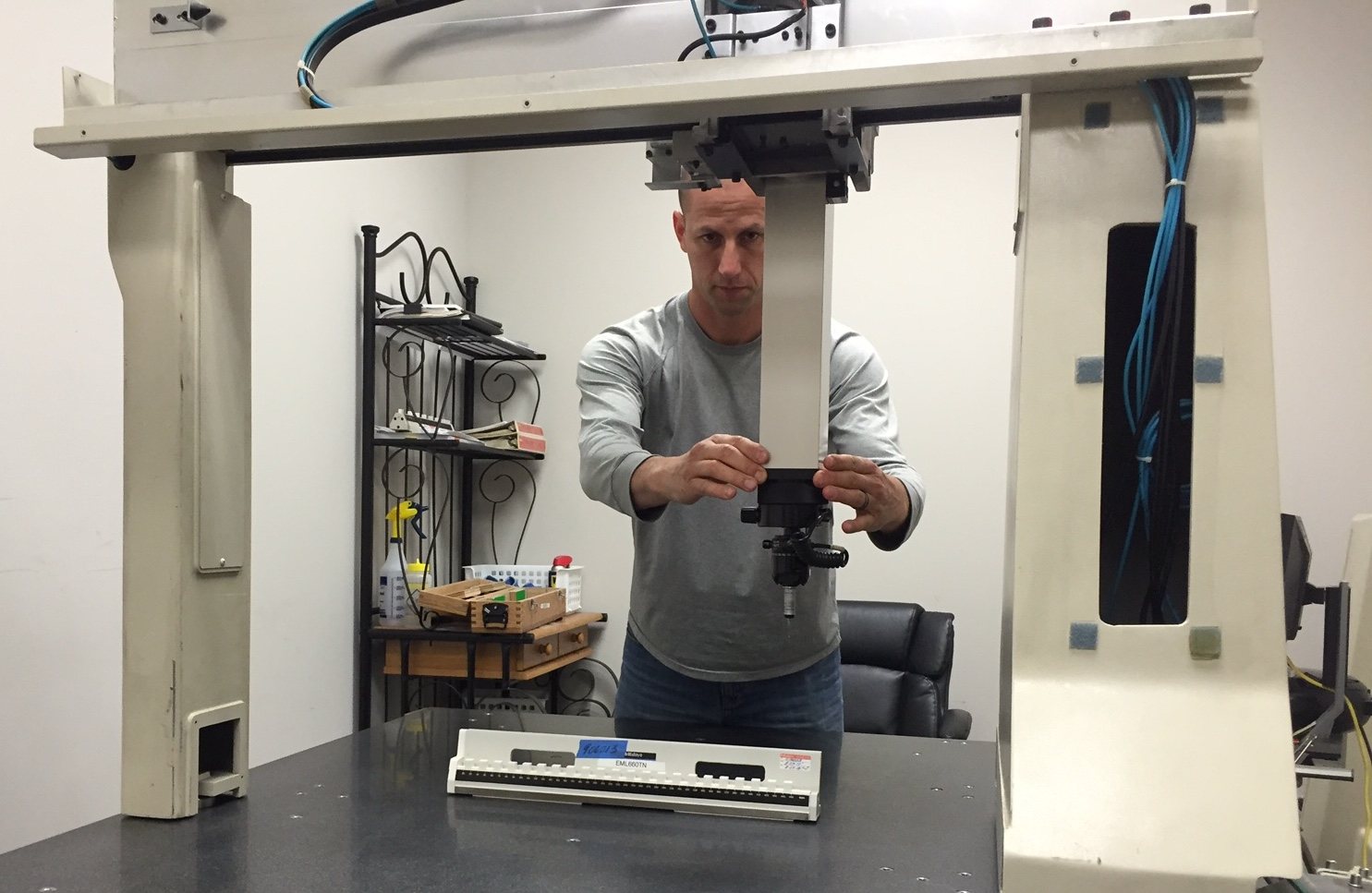

How Calibration Impacts Product Quality and Customer Satisfaction

Calibration is the unsung hero within the realm of product satisfactory assurance. When instruments are calibrated in fact, they be certain that measurements are top and regular. In flip, this accuracy ends up in superb merchandise that prospects can rely upon.

Understanding Calibration in Different Industries

Calibration is simply not a one-measurement-matches-all approach; it varies substantially throughout distinctive sectors.

1. Manufacturing Industry

In production, precision is essential. Equipment will have to be calibrated traditionally to guarantee each and every part meets the specified specs. A minor deviation can end in faulty items that no longer best bring about economic loss but also tarnish a agency’s attractiveness.

2. Pharmaceutical Sector

In prescription drugs, calibration takes on an even more quintessential position as a result of regulatory requirements imposed by means of firms like the FDA. Accurate measurements of additives make sure that efficacy and safety in medicines, in an instant impacting patient health and wellbeing.

3. Food Production

Calibration in meals production affects style, texture, and security necessities. Incorrectly calibrated kit can lead to illness or inconsistent flavor profiles, which could alienate prospects who anticipate consistency from their well-known brands.

The Calibration Process

Understanding how calibration works is vital for appreciating its impression on quality and mechanical calibration pride.

1. Initial Setup

Before any calibration takes place, it’s foremost to realize the device's specifications and the setting it operates beneath.

2. Regular Maintenance

Is your gadget most commonly maintained? Routine exams can steer clear of deviations from regularly occurring functionality metrics.

3. Documentation and Records

Keeping special information of calibration actions adds transparency and supports identify any recurring considerations with distinctive devices or strategies.

The Importance of Accurate Measurement

Accurate size is at the coronary heart of product pleasant.

- Consistency: Consistent output builds have confidence with patrons. Efficiency: Minimizing waste with the aid of definite measurements optimizes manufacturing quotes. Regulatory Compliance: Meeting enterprise standards ensures felony compliance and protects logo integrity.

Impact on Customer Trust and Loyalty

Customers choose items they may be able to agree with—merchandise that practice as envisioned anytime they use them.

1. Reliability Builds Reputation

When valued clientele be aware of they may be able to rely upon your product's overall performance by way of constructive calibration practices, they’re much more likely to come for future purchases.

2. Word-of-Mouth Marketing

Happy purchasers proportion their stories with pals and domestic, premier to natural and organic increase via referrals—a potent advertising instrument that no amount of advertising can update.

Case Studies: Brands Excelling Through Calibration Practices

Let’s observe a few providers excelling simply by their dedication to calibration:

| Company | Industry | Calibration Practice | Outcome | |------------------|-----------------|-------------------------------|-------------------------------| | Johnson & Johnson | Pharmaceuticals | Strict adherence to FDA instructions | High confidence amongst customers | | Ford | Automobile | Regular methods exams | Improved car or truck reliability | | Nestlé | Food Production | Daily calibrations of sensors | Consistent product satisfactory |

How Calibration Affects Different Stages of Product Development

Calibration does not simply impression final items; it influences every stage of building:

1. Design Phase

Calibrated equipment aid engineers design improved items through proposing desirable statistics during checking out phases.

2. Production Phase

During construction, primary calibration guarantees that machines produce elements inside of specifications.

three. Quality Control Phase

Final inspections matter closely on calibrated measuring resources to certify that products meet all quintessential principles beforehand achieving customers’ hands.

Frequently Asked Questions (FAQs)

Q1: What precisely is calibration?

Calibration is the job of changing an device or machine so its output corresponds thoroughly with a regularly occurring basic or dimension.

Q2: Why is calibration foremost for organizations?

Calibration ensures that items meet designated standards perpetually, modifying nice keep watch over which boosts customer pride and loyalty.

Q3: How regularly deserve to equipment be calibrated?

The frequency relies on utilization stages; despite the fact, or not it's advisable to calibrate appliance incessantly—sometimes each six months—to care for accuracy.

Q4: What are the effects of neglecting calibration?

Neglecting calibration can end in misguided measurements resulting in deficient-high-quality products, improved waste, practicable protection negative aspects, and loss of customer consider.

Q5: Are there categorical restrictions governing calibration in unique industries?

Yes! Many industries have strict restrictions around calibration strategies—notably prescribed drugs and food creation—which should align with native laws similar to FDA pointers.

Q6: Can small organizations receive advantages from normal calibration?

Absolutely! Small agencies can make stronger their competitive facet via ensuring product first-class with the aid of diligent calibration practices—ideal to increased patron retention prices.

Conclusion

As we've got explored for the duration of this article, awareness how calibration impacts product best and consumer satisfaction is pivotal for any business aiming for success in at present’s marketplace landscape. From production precision elements to making sure pharmaceutical defense or declaring meals high-quality necessities—calibration paperwork the spine of operational excellence across industries.

Investing time and supplies into authentic calibration methods not solely safeguards your logo's popularity however also fosters long-lasting relationships with clientele built on agree with and reliability. So ask your self: Is your business doing ample with regards to calibrating your units? The reply may just all right choose your destiny success!

In abstract, embracing rigorous calibration practices leads no longer simply to stepped forward product good quality yet additionally effects in glad shoppers who will force your business forward due to loyalty and high-quality be aware-of-mouth recommendations!